The types of finishing in textiles define the final quality, functionality, and appeal of fabrics. Whether it’s a soft touch, wrinkle resistance, or moisture control, the textile finishing process tailors fabrics to specific uses across fashion, medical, home, and technical sectors. In this guide, we break down all types finishing methods — mechanical, chemical, aesthetic, and functional — with examples and industrial relevance

What Is Textile Finishing?

Textile finishing refers to any treatment applied to a fabric after dyeing and printing but before converting it into a final product. These finishes enhance the fabric’s appearance, performance, and feel. Depending on the method, finishes may be temporary, semi-durable, or durable.

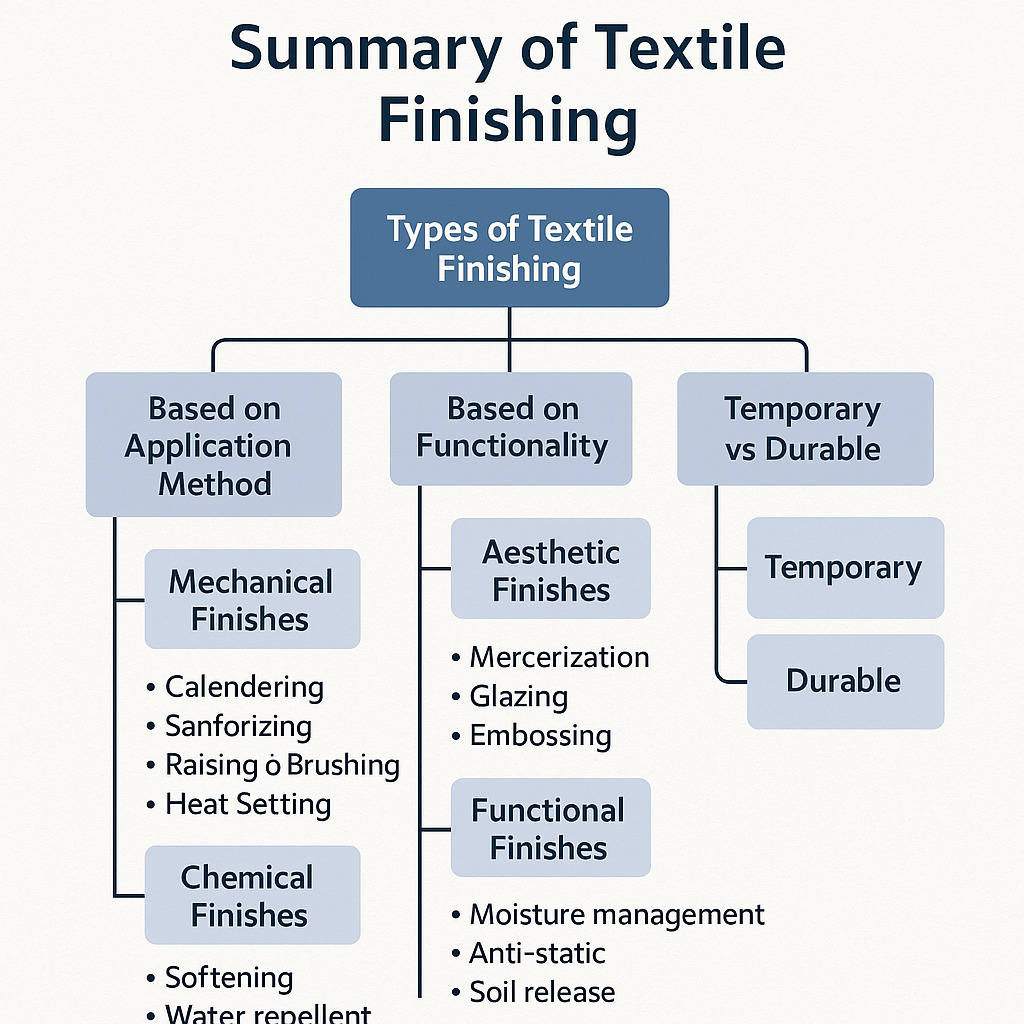

Classification of Types of Finishing in Textiles

The types of textile finishing are typically grouped based on:

Application Method

Functionality (Aesthetic or Performance-based)

Durability (Temporary vs Permanent)

Types of Finishing in Textiles Based on Application Method

Mechanical Finishes in Textiles

Mechanical finishing involves physical modification of the fabric surface using pressure, heat, or abrasion.

Common Mechanical Finishes:

Calendering – Smooths fabric by passing it between heated rollers.

Raising/Brushing – Lifts fibers for a soft, warm texture (e.g., fleece).

Sanforizing – Pre-shrinks cotton to avoid shrinkage after washing.

Heat Setting – Stabilizes synthetic fabrics to prevent distortion.

Shearing – Trims fiber ends for an even surface.

Chemical Finishes in Textiles

Chemical finishes alter the fiber structure or coat the surface using chemical agents.

Examples of Chemical Finishing in Textiles:

Softening – Adds comfort using silicone or fatty acid derivatives.

Water Repellent Finish – Makes fabric resistant to moisture (e.g., DWR, silicones).

Wrinkle-Resistant Finish – Prevents creasing using resins or formaldehyde-free agents.

Flame Retardant Finish – Reduces flammability for safety textiles.

Antimicrobial Finish – Prevents bacterial growth for hygiene applications.

UV Protection Finish – Blocks ultraviolet rays in outdoor wear.

Types of Finishing in Textiles Based on Functionality

Aesthetic Finishes in Textiles

Aesthetic finishes enhance visual appeal, luster, and texture of the fabric.

Popular Aesthetic Finishes:

Mercerization – Increases luster, strength, and dye uptake in cotton.

Glazing – Adds shine using wax or resin, followed by calendering.

Embossing – Creates raised patterns using engraved rollers.

Bleaching – Removes natural color to whiten fabric.

Functional Finishes in Textiles

Functional finishes improve performance and utility for specific applications.

Key Functional Finishes:

Moisture Management / Wicking – Moves sweat away from the body.

Anti-static Finish – Neutralizes static charge in synthetics.

Soil Release Finish – Eases removal of stains and dirt.

Anti-microbial – Adds hygiene benefits for medical or sports textiles.

Thermo-regulating Finish – Maintains comfort in varying temperatures.

Types of Finishing in Textiles by Durability

| Finish Type | Description | Example |

|---|---|---|

| Temporary | Lasts 1–2 washes; easily removed | Starch finish |

| Semi-durable | Lasts several washes; eventually fades | Softening with fatty acid agents |

| Durable/Permanent | Chemically bonded; remains throughout fabric lifespan | Wrinkle-free resin finish |

Eco-Friendly Types of Finishing in Textiles

Sustainability is reshaping textile finishing methods through:

Enzymatic Finishing – Replaces harsh chemicals with natural enzymes.

Plasma Treatment – Alters fiber surfaces without water or chemicals.

Supercritical CO₂ Finishing – Waterless dyeing/finishing using pressurized CO₂.

Nano Finishing – Applies nanoparticles for advanced performance (e.g., self-cleaning).

FAQs: People Also Ask about Types of Finishing in Textiles

What are the types of finishing in textiles?

They include mechanical, chemical, aesthetic, and functional finishes, used to modify performance or appearance of fabrics.

How many types of textile finishing are there?

Generally, there are three major types based on application: mechanical, chemical, and functional, with multiple subtypes in each.

What is aesthetic finishing in textiles?

It enhances visual appeal such as gloss, color, or texture. Examples include mercerizing, glazing, and embossing.

What is the difference between dyeing and finishing?

Dyeing gives color, while finishing adds functionality or feel, like water repellency, softness, or antimicrobial protection.

What are functional finishes in textiles?

They improve fabric performance, such as moisture management, anti-odor, UV protection, and flame retardancy.

Industry-Wise Application of Different Finishing Types

| Sector | Relevant Finishes |

|---|---|

| Fashion/Apparel | Softening, wrinkle-free, stain resistance |

| Home Textiles | Flame retardant, antimicrobial, anti-static |

| Medical | Antimicrobial, anti-static, barrier coatings |

| Athleisure | Wicking, odor control, stretch recovery |

| Industrial/Workwear | Flame retardant, soil release, UV protection |

Recent Innovations in Textile Finishing

Smart Finishes – Thermochromic, photochromic, or sensor-integrated textiles

Bio-based Chemicals – Derived from corn, soy, or other renewable sources

Digital Finishing – Contactless finishing via inkjet and laser systems

Challenges in Textile Finishing

Environmental Impact – Water and chemical use in traditional methods

Chemical Safety – Potential toxicity from residues (e.g., formaldehyde)

Durability Issues – Some finishes wash off quickly

Cost Constraints – Advanced finishes may be expensive for mass-market use

Conclusion: Choosing the Right Type of Finishing in Textiles

Understanding the types of finishing helps manufacturers tailor products to market demands. Whether the goal is enhanced aesthetics, performance, or sustainability, finishing processes offer endless customization options. As eco-conscious innovation grows, the future of textile finishing will be smarter, greener, and more functional than ever.